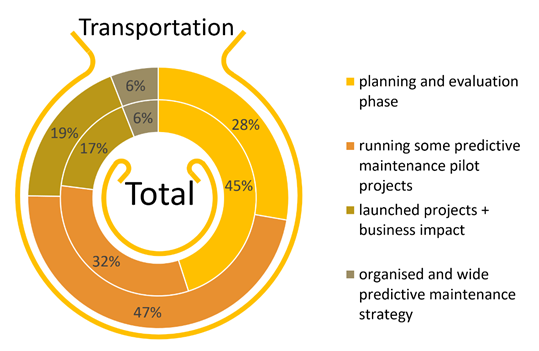

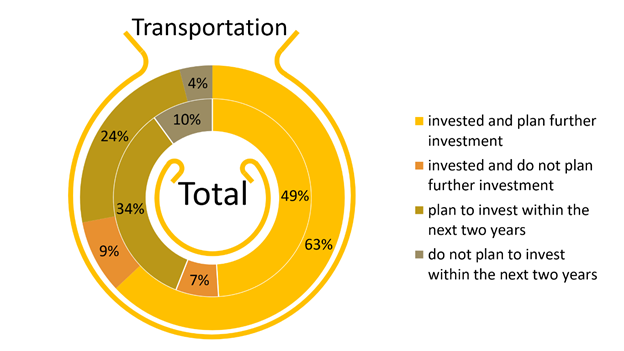

While the penetration ratio of “predictive maintenance concept” is more than 80% in industries, the statistics released by General Electric shows that the transportation sector has already stepped in this way. In this sector, there are signs of faster progress, and they have already brought the first examples into practice. The same investigation compares the trend of development in railway industry according to figures below. The percentage of launched business project and pilot projects are higher. Furthermore, transportation industries have already invested in predictive maintenance, roughly 15% more in comparison to question all industries in European organization.

how big is the market?

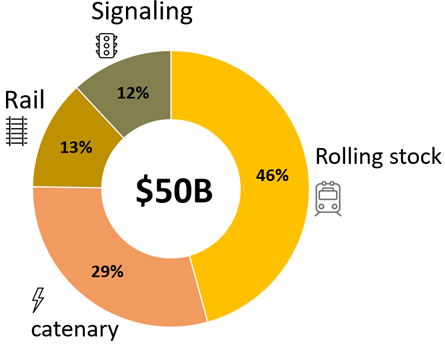

The market size is the leading signal for enterprises to enter the game. It is considered that the global market for maintenance in the railway industry is 50 billion per year. In this case, the global projected market for predictive maintenance is growing from 9.0 to 12.3 billion from 2019 to 2024; that means annual growth as significant as 6.4%. The figure below illustrates the percentage of various sectors in the maintenance market.

estimations of generated value

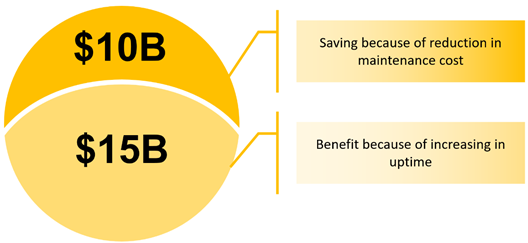

One hundred days per year, it is a rough estimation of the days a train stays in the workshop for manual failure diagnostics. Predictive maintenance can generally reduce this time by 60%. Therefore, predictive maintenance in the railway industry increases uptime by about 18%. Providing predictive maintenance measure for both catenary and pantographs will result in a 20% reduction in the maintenance cost of the catenary. Considering the total market of maintenance in the figure above, the total saved cost of maintenance is about $25B. The significant portion belongs to the generated value of about $ 15 B due to the increase in uptime. In addition, it is estimated to reduce the maintenance cost in rolling stock, catenary, rail, and signalling by about $ 10 B per year. The share of generated value is represented in the figure below.