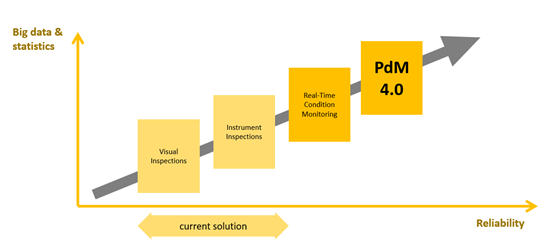

Railway transportation systems, including rolling stocks and infrastructures, are capital intensive. Accordingly, they are counted as long-term investments. Increasing the competition among manufacturers and operators has resulted in shifting toward advanced services, higher reliability, and reducing the cost of operation. Shrinking the maintenance cost is an appropriate option to minimize the total cost of the system performance. In recent years, condition monitoring has already developed and applied to approach this goal. It is estimated that these actions result in a 10% to 15% reduction in maintenance cost and up to 60% decrease in maintenance duration. [reported by McKinsey]. The well-known maturity matrix of predictive maintenance is represented in the following figure.

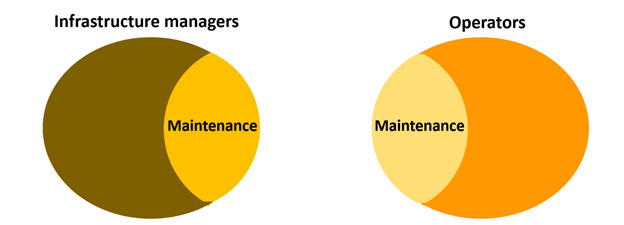

The following figure illustrates the conventional approach of maintenance has defined isolated rule and regulations of maintenance for rolling stocks and infrastructures.

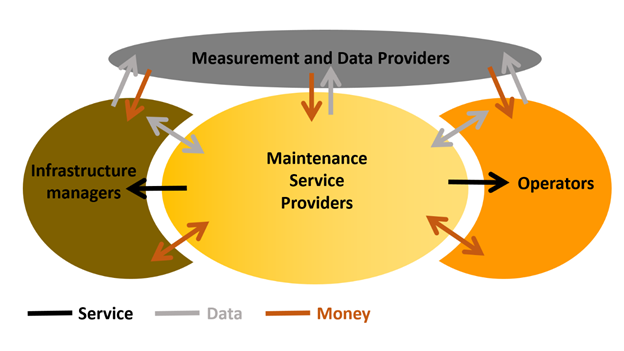

The innovative and efficient condition monitoring based maintenances are applicable for both infrastructures and rolling stock operators via “Maintenance service provides”.

It is clear that for getting the advantages of the innovative solutions, there are many questions to answer, changes to adopt, challenges to overcome.

- The first question is defining the responsible partner for digitalizing the maintenance. The answer to this question is the backbone of in-house or partnership business models. Outsourcing the maintenance cost provides the third parties with the opportunity of being a maintenance administrator. However, the third party may include a wide range of players including, infrastructure managers, operators, OEM or data analysis companies.

- A change from scheduled and regulated maintenance to condition-based maintenance not only needs precise analysis criteria, but also a synchronized maintenance implementation, spare part supply and coincident supply of supplementary substitution services are required.

- As data is the basis of the described business, the data-sharing partnership can be a challenge to solve before stablishing the whole industry. Data ownership, verification and validation, data sharing rights, regulations and data security are the new issues the needs a clear prescription of roles and responsibilities is the next impediment.