In our fast-paced world of technological advancements, integrating artificial intelligence (AI) into railway operations is reshaping how we think about transportation. Railways are entering a new era characterized by enhanced efficiency, safety, and reliability through the fusion of AI with predictive analytics and maintenance strategies.

Gone are the days of reactive maintenance practices, where issues were addressed only after they occurred. With AI-powered predictive analytics, railway operators can foresee potential problems, optimize maintenance schedules, and ensure smooth train operations. This transformative approach revolutionizes the railway industry, offering many benefits and real-world applications.

In this article, we delve into the diverse advantages of AI in railways, exploring how it is driving positive change across the transportation sector. From predictive maintenance to optimized operations, AI is unlocking new possibilities for railways, ushering in a future where trains are safer, more reliable, and more efficient.

What is Predictive Maintenance, and Why Is It Important?

Predictive maintenance is a futuristic maintenance practice that utilizes AI-powered predictive analytics to anticipate potential equipment failures before they occur. Through analyzing real-time data from sensors and other references, predictive maintenance helps railway operators detect early warning signs of faults or malfunctions in critical components such as locomotives and track infrastructure.

Here are some of the most essential benefits of predictive maintenance for the railway industry.

1.Improved Reliability

By enabling early detection of potential issues, predictive maintenance enhances safety by reducing the risk of accidents and derailments. This proactive approach safeguards passengers and crew, ensuring a more reliable and secure railway operation.

Predictive maintenance plays a crucial role in maintain the safety and reliability of railway industry. It can significantly decrease the chance of accidents or costly damages to the trains and overhead. Predictive maintenance allows for the optimization of maintenance schedules based on the actual condition of equipment rather than predefined time intervals.

This ensures that maintenance tasks are performed when necessary, minimizing downtime while maximizing equipment reliability.

2.Cost Savings and Capability

Predictive maintenance helps minimize downtime and disruptions by addressing maintenance needs before they escalate into costly breakdowns. This consequences in decreased operational costs and enhanced service reliability. Optimized maintenance schedules based on real-time data allocation ensure efficient resource utilization and minimize unnecessary expenses.

3.Extended Equipment Durability

By proactively addressing maintenance needs, predictive maintenance helps mitigate wear and tear on rolling stock and infrastructure. This extends the usability of valuable assets and prevents costly replacements, ultimately leading to increased longevity and sustainability of railway operations.

4.Mitigating Safety Risks

Regular monitoring and analysis of equipment condition enable the detection of potential safety hazards, such as worn-out components or abnormal operating conditions. By addressing these issues proactively, predictive maintenance helps mitigate safety risks and ensures a safer working environment for personnel.

In general, predictive maintenance offers the railroad industry the advantages of improved safety, cost savings, and extended asset lifespan, making it a valuable approach for optimizing maintenance practices and ensuring efficient and reliable transportation.

How Can AI Help and Enhance Predictive Maintenance in the Railway Industry?

AI plays a pivotal role in transforming predictive maintenance practices in the railway industry, offering many benefits that revolutionize how maintenance is conducted and enhance railway operations’ overall efficiency and reliability.

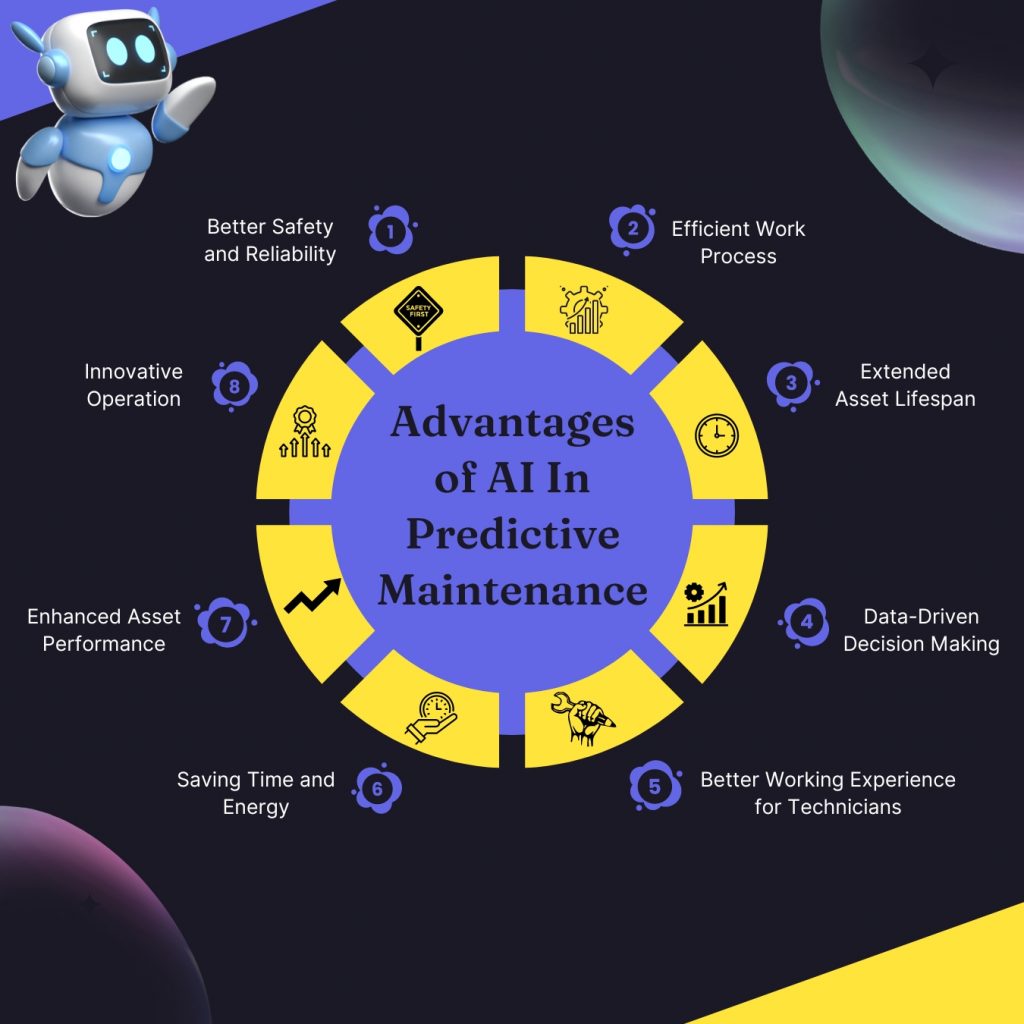

1.Better Safety and Reliability

By leveraging AI-powered predictive analytics, railway operators can detect potential issues early on, significantly reducing the risk of accidents and derailments. Real-time monitoring of critical components such as tracks and rolling stock allows for the timely identification of faults, ensuring the safety of passengers and crew members while enhancing the reliability of train operations.

2.Efficient Work Process

Predictive AI-powered maintenance minimizes downtime and disruptions, leading to substantial cost savings for railway operators. By optimizing maintenance schedules based on real-time data insights, resources are allocated more efficiently, resulting in reduced operational costs over time. Moreover, proactive maintenance practices help prevent costly breakdowns, contributing to cost-effectiveness.

3.Extended Asset Lifespan

AI-driven predictive maintenance enables operators to proactively address maintenance needs, mitigating wear and tear on railway assets. By placing potential problems before they escalate, AI helps prolong the lifespan of critical components, thereby avoiding costly replacements and ensuring the long-term sustainability of railway infrastructure.

4.Effective Decision Making

AI in predictive maintenance facilitates data-driven decision-making by analyzing vast amounts of sensor data in real time. Operators can prioritize repairs and strategically allocate resources by accurately predicting maintenance needs and improving operational efficiency and safety across the railway network.

5.Better Working Experience for Technicians

Using AI can bring many benefits and advantages for technicians and maintenance workers. AI can help them notify issues and their location better and faster. Therefore, they need to know the area of the problem before getting into the field.

Plus, AI can help them to analyze data faster and more quickly. This way, the workforce can be more prepared and equipped to deal with overhead problems and offer a quick and efficient solution.

6.Saving Time and Energy

There is no need to mention AI’s benefits for faster processing issues and daily tasks. Implementing AI to speed up daily and routine operations is not restricted to the railway industry. One of the primary reasons for using AI in any industry is to get things done faster.

The same thing is true for the railway industry as it can solve and handle complicated issues, such as maintenance problems, much quicker than the human workforce. As mentioned before, it can save a great deal of energy by pointing out the exact area of the problem overhead so technicians can solve it faster and more quickly.

7.Enhanced Asset Performance

AI empowers operators to optimize the performance of railway assets by identifying and addressing performance bottlenecks. Through continuous monitoring and analysis, AI-driven predictive analytics enable operators to implement targeted improvements, ensuring consistent and optimal performance of the entire railway system.

Additionally, timely maintenance and calibration activities help reduce energy consumption and operational costs while maximizing asset utilization.

8.Innovative Operation

Embracing AI-powered predictive maintenance gives railway operators a competitive edge in the industry. By offering higher service reliability and customer satisfaction levels, operators can differentiate themselves from traditional rail operators. Moreover, adopting modern, efficient, and sustainable transportation solutions attract tech-savvy customers and investors, positioning railways as leaders in innovation and excellence.

Conclusion

In conclusion, AI-driven predictive maintenance transforms the railway industry by optimizing maintenance practices, enhancing safety and reliability, and providing a competitive advantage in an ever-evolving transportation landscape. By harnessing the power of AI, railway operators can unlock new opportunities for efficiency, sustainability, and growth, ensuring the continued success of railway transportation in the modern era.

However, there are many questions left to be answered about the benefits and usage of AI in the railway industry. Shortly, we can know more about the impact and influence of AI on managing railway problems, such as predictive maintenance. As we go further, more aspects of AI effects will be revealed, and we can be more specific about its advantages for railways.

Reference

appinventiv.com/blog/ai-in-railways