Most of the overhead catenary systems are suffering from icing in winter. De-icing technology can be divided into three categories, which are thermal melting ice, mechanical icebreaking, natural passive methods.

Vibropantographs or secondary “ice cutter” pantographs are some examples of mechanical icebreaking. You can read more in this article.

The main week point of mechanical ice breaking is their operation speed and interruption in train service.

Natural passive methods are the methods which coat the contact wire with a chemical component (like mono-ethylene glycol). The solution of Stemmann-technick (Non-Icing System) for coting contact wire is shown in the following image.

The coating process should be repeated every 3 or 4 days and the operation speed for this device is 30km/h.

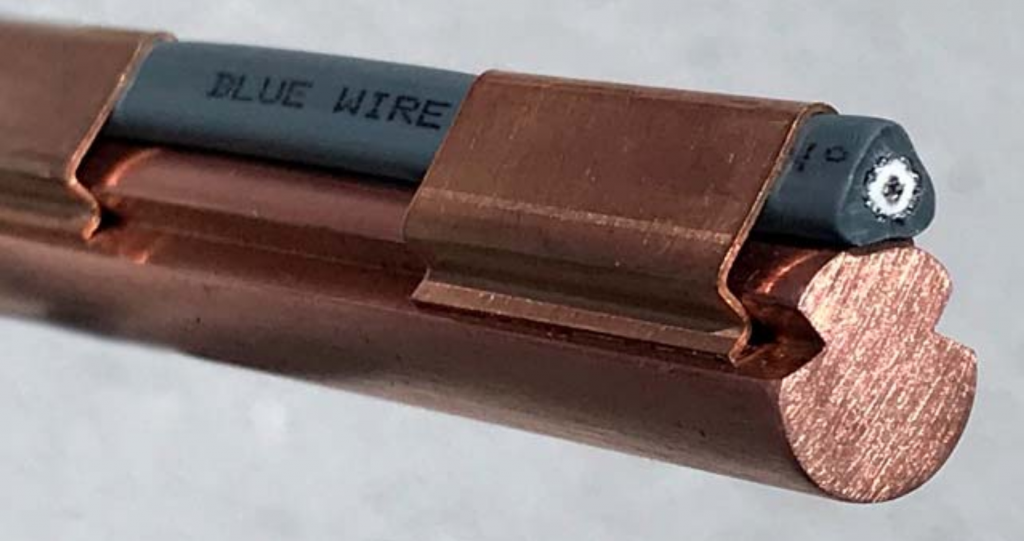

The thermal melting ice is common in main lines and high-speed lines. This approach could be deployed either by using “BLUE WIRE” (figure below), proposed by SAN or injecting current to contact wire directly.

The coating process should be repeated every 3 or 4 days and the operation speed for this device is 30km/h.

The thermal melting ice is common in main lines and high-speed lines. This approach could be deployed either by using “BLUE WIRE” (figure below), proposed by SAN or injecting current to contact wire directly.

This approach has a significant disadvantage in tunnels which is the target of this article.

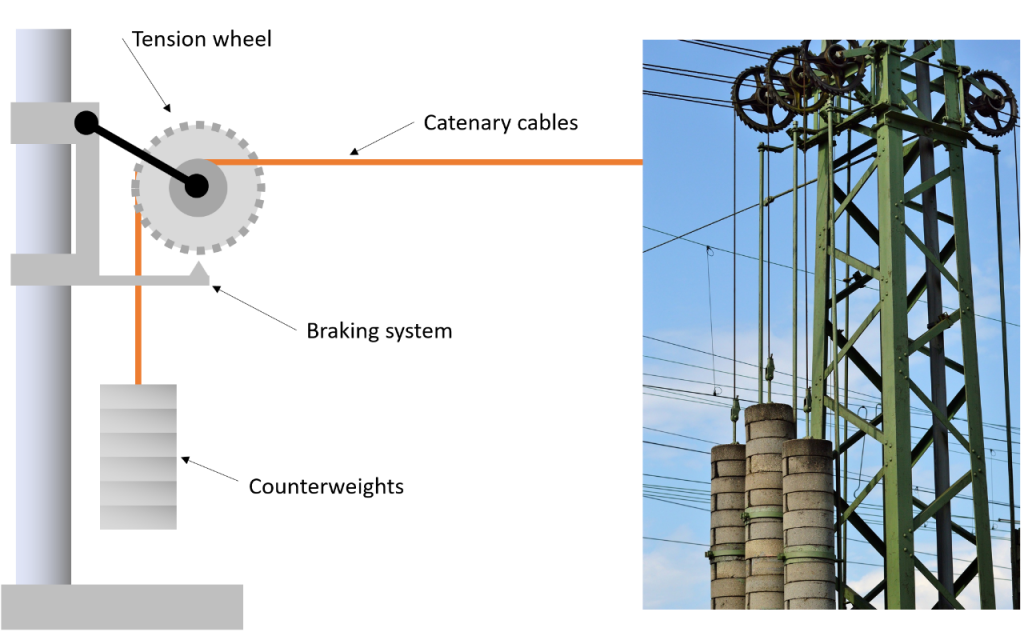

Tension wheels are used in the catenary lines of electric railways to keep the height of the contact wire constant. In the event of breakage of the catenary wire or contact wire, the tension wheel prevents the counterweights from contacting the ground, which avoids further deformation of the catenary system.

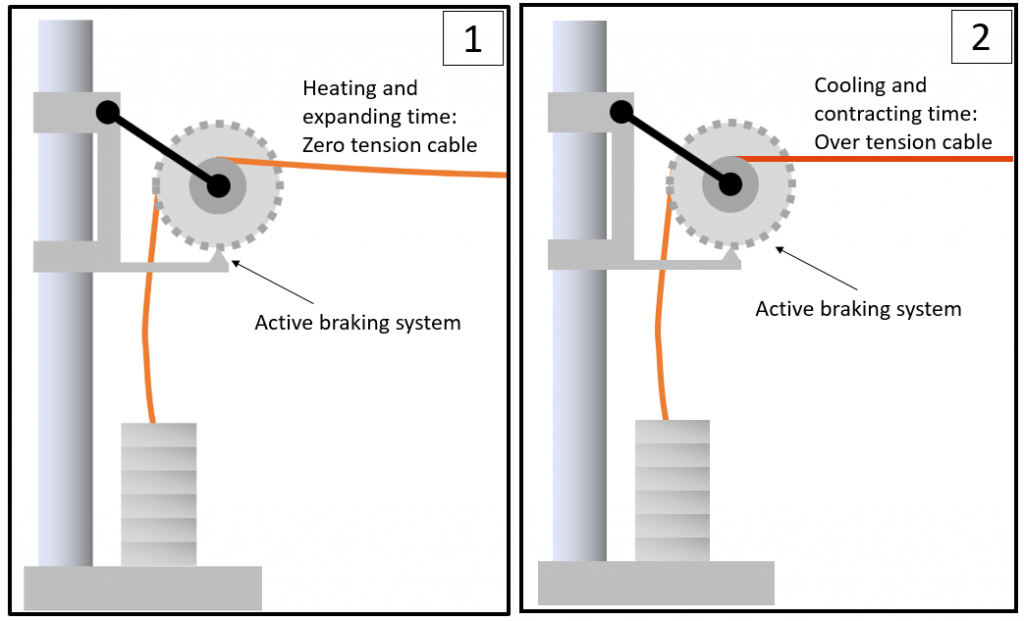

During the defrosting process, the temperature of cable in tunnels raised significantly and the cables expand more than the range which the tension wheel is designed for. Therefore the counterweights touch the ground and the tension in cables become zero (figure 1). The balance of tension in tension wheel changes, and due to the weight of the wheel, it goes to the braking system. The braking system stays active, and when the cable gets cold again, the braking system doesn’t let the tension wheel to roll and raise up the counterweights. The more cables get cold, the higher tension appears in tension wheel and this tension can cause damage to catenary.

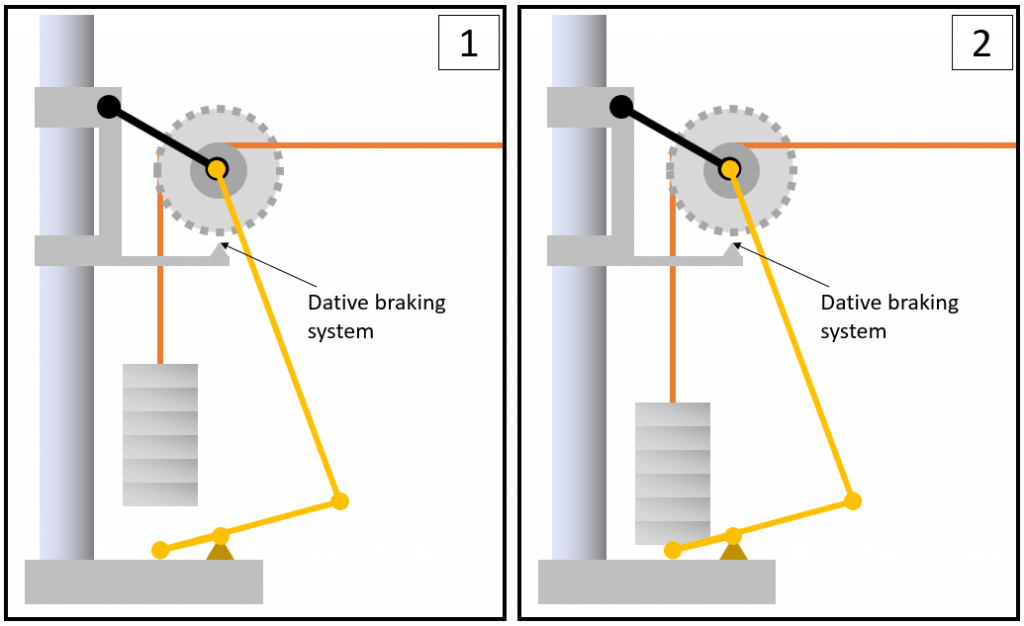

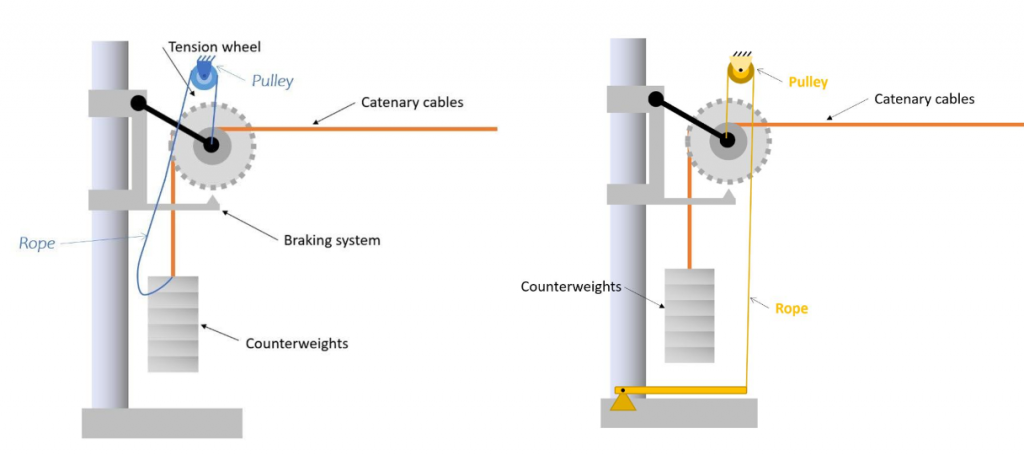

In the following figure, a schematic of the concept of a solution is proposed. In this idea, the yellow linkage feels the weight of counterweights and change the static balance of the wheel, in a way that the braking system does not active any more.

The proposed solution is an open concept and needs more feedback from field experts and customers.

The following section is added on 19.01.2020 based on comments on this article by Kamran Koochakalavi & Marcel Glaser & Fritjof Aufschläger & Soheyl Moradi

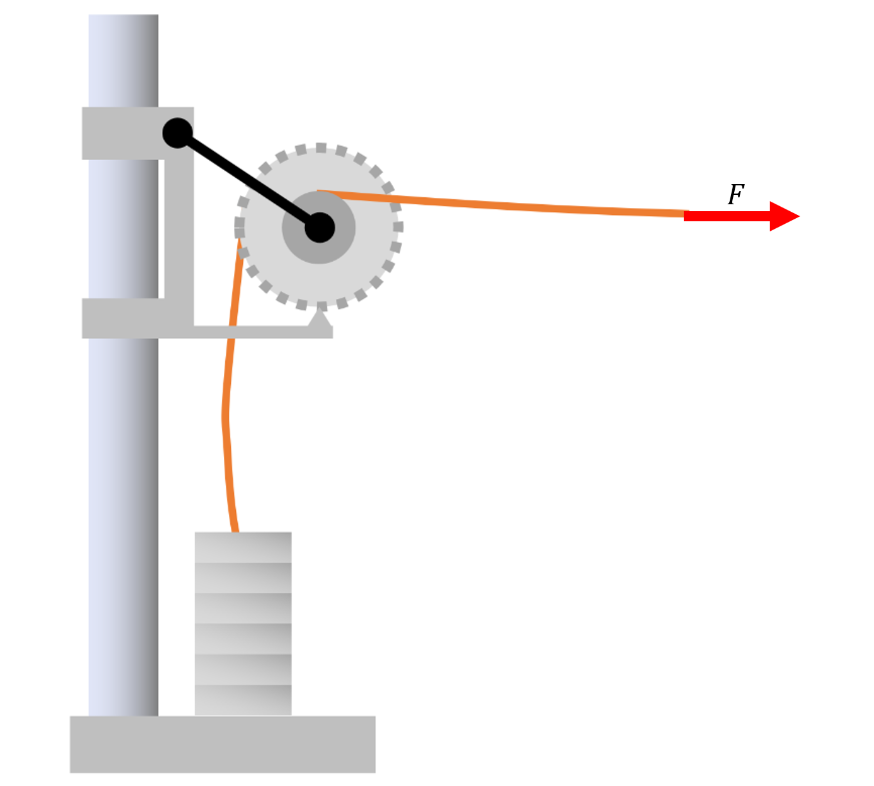

In order to simplify the question, the following problem is proposed. The question is that what would happen if the force F gradually increase? The weights will rise up or the wheel will block?

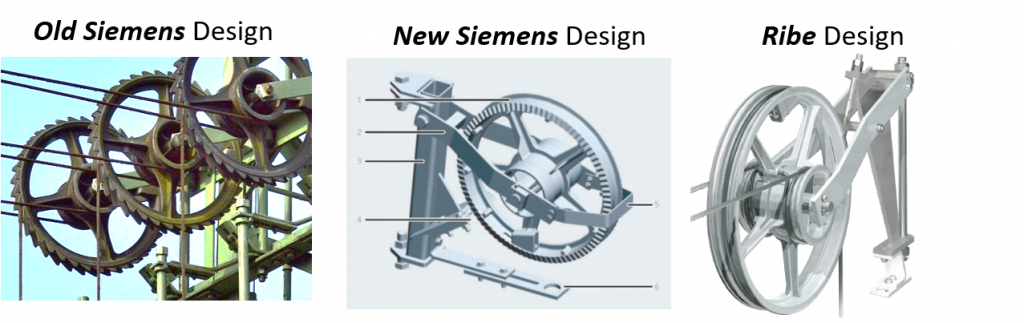

The answer to this question depends on the type of tension wheel. The following figure shows three considered tension wheel in Germany.

The shape of Teeth in the old and new design of siemens is important for its behaviour in the mentioned problem. The following figure shows the free body diagram of the wheel for the mentioned problem.

This equation shows if the angle of the teeth of the wheel be zero (same as the new design of siemens) and the mechanical advantage of the wheel is 0.3, considering 0.3 for the static friction coefficient, 3kN is required for unlocking the wheel. It is worth to mention that by lubricating breaking point (reducing friction coefficient) the probability of locking will be reduced. regarding to cable break tension wheel, the angle of the breaking cable defines the locking condition and similar calculation should be done by the designer of the tension wheel.

Following figures propose more practical techniques to prevent this problem.

For more articles, please visit our website: www.pantohealth.com

One response to “When a solution makes a new problem! Thermal ice melting of the contact wire locks the tension wheels in the tunnels and causes high tension.”

If you want to use the photo it would also be good to check with the artist beforehand in case it is subject to copyright. Best wishes. Aaren Reggis Sela